Share

Pin

Tweet

Send

Share

Send

For the manufacture of this apparatus, I bought a galvanized bucket of 15 liters, it is possible less, but then I will have to change the water more often. In the store for goods for gas equipment of automobiles, he acquired 2 meters of a copper tube of 8 mm. On a suitable cylinder, I rolled the tube into rings, leaving straight ends for the entry of vapors and the exit of condensate, a coil was obtained.

I drilled a hole under the tube in the wall of the bucket, near the bottom, and led the lower end of the coil into it, and secured the upper one with a clamp and two bolts. To make the outlet of the lower end tight, it can be welded, but I did it easier, coated it with cold welding, thought temporarily, but I have been using it for the second year.

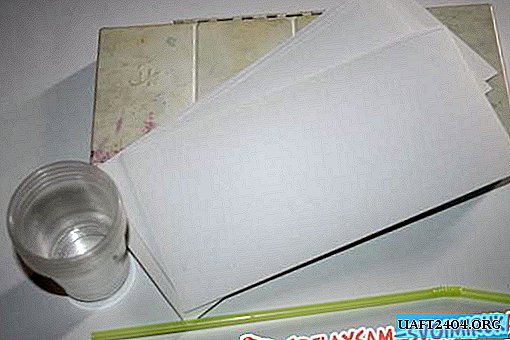

The device itself is ready, now we need a distillation cube and its connection with the device. It is best to take an aluminum can for the cube, but I have all of them under honey and there are no free ones. I had to be wise. He took an enameled large pan with a lid. I inserted a fitting with a 1/2 inch thread into the lid and, using two nuts and a gasket, secured it, the silicone gasket, since it is impossible to put the rubber, when it is heated, it will transfer its smell to the vapor, and that to the final product.

Now you need to seal the lid, the rubber here is also not suitable. You can try to make a silicone gasket, but again I did it easier, filled the inner recess on the lid with a cool dough of flour and water. Now you need to press the lid, any rod that fits into the lid ear is suitable, its ends and pan handles are connected by wire twisting, it will create a pressure. Here you can use screw or rubber ties, in general, complete freedom for imagination. Now it’s the turn of connecting the apparatus and the pan. It is better to do this with a gas bellows, it does not have a rubber hose inside. I connected it to the distillation cube through a silicone gasket, and to the apparatus through a fitting, the latter fits tightly onto the tube.

5.jpg

That's the whole design, minimum costs, is going to quickly and simply work with it conveniently. Braga is poured into a distillation cube, put on the fire of a gas stove, gas comes from a cylinder of propane. It is only necessary to take into account that the mash on honey is very foaming and can get into the coil, so it is not filled in an entire cube, you can add a little butter or milk, this prevents the formation of foam. The apparatus is installed lower in level than the cube, and preferably with a slight slope towards the condensate drain pipe, so that a liquid plug does not form in the coil. Gas at the beginning of the process should be kept to a minimum, water is poured into the bucket, preferably cold and it remains to wait until the mash is heated, its vapor will begin to condense in the coil. The first outlet of moonshine contains many not very good impurities that have a pronounced smell of solvent, they are called heads. This part must be poured or used for household needs, its amount is determined empirically, I cut off about a tenth of the share. After that, the gas pressure can be increased, the process will go faster. Gradually, the pairs in the coil heat the water in a bucket, it collects in the upper layers, it is drained with a ladle and refilled with cold. With increasing temperature, heavy fractions, including fusel oils, start to evaporate from the mash, which give the moonshine an unpleasant odor, so the process must be completed on time. I determine this moment by the burning of moonshine, if it stops flashing with a blue flame on paper, then enough. In the end result, out of ten liters of mash, I get about two liters of moonshine, with a strength of about 50%. I also want to say that it is better to do distillation in cool weather, and if it is hot in the afternoon, then do it early in the morning, then less often you will have to change the water in the bucket. The resulting product, in principle, is ready for use, but it can be done better, of course, well overtaken again, but you can do it by passing through a household filter, or through a plastic bottle filled with charcoal for barbecue grills. You can also give it a pleasant taste and color with various additives, it is easiest to melt sugar in a spoon in a fire and add hot to the drink, it will acquire a noble cognac color. Good and fragrance tinctures on herbs and berries. I use the collection of thyme, St. John's wort and oregano. Of the berries, I prefer chokeberry and cherry. Here everyone can find their favorite composition, there are a lot of options. I hope that my advice will be useful not only to beekeepers, but also to simple summer residents. If you replace honey with sugar, then everyone can use them. Good luck and enjoy the next summer season.

Share

Pin

Tweet

Send

Share

Send