Share

Pin

Tweet

Send

Share

Send

Our barbecue will be with the continuous reproduction of coal from firewood. This design is convenient in that it does not need to wait for the burning of wood logs to cook on charcoal. They burn in a small chamber, the walls of which rise above the grill. And coals glowing with heat move to the cooking zone. The whole process takes a little time, so such a barbecue will undoubtedly please all hungry travelers. So, let's get started!

Required resources

Materials:

- Sheet steel, thickness - 1-2 mm;

- One-piece metal square 10x10 mm;

- Profile pipe 15x15 mm;

- The pipe is round, diameter - 18-20 mm;

- Metal bar with a section of 4-5 mm.

Instruments:

- Plasma Cutter

- Welding inverter with electrodes;

- Gas welding or a propane torch for heating metal;

- Clamp, pliers, brush for metal;

- Hammer, tape measure, chalk technical pencil.

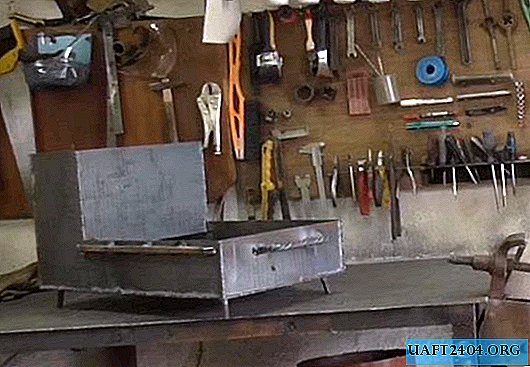

Making brazier from sheet steel

We put a sheet of steel on the goats, and begin marking the parts. Following the drawing, we cut out each structural element with a plasma cutter.

We distribute the cutting economically on the sheet so that less waste remains. It is most practical to first place large parts, then small ones between them. We add the numbered finished parts separately.

We set the side wall perpendicular to the bottom of the barbecue, and grab in several places by welding. Then we put the end part of the box and the second side wall. We fasten them together using the same method of short tacking by welding.

We close the box with a low end strip and limit the exhaust zone to a vertical wall. It turns out something like an open-top l-shaped knee.

We pass all the seized joints with a continuous seam. You can clean them with a grinder and a grinding disk.

We reinforce the side walls with two handles from a profile pipe 15x15 mm. We cut the finished segments slightly from the ends to the mustache, leaving the plane intact. We subsequently bend it with a hammer, and boil it.

The legs for the barbecue will be removable. To fix them, we weld small pieces of a cast square rod at the corners of the barbecue. For stability, we do this with a slight outward inclination. The angle of inclination can then be adjusted by hand. We cut the legs from a round pipe. We select its diameter so that the racks easily, but tightly fit into the square stops.

The brazier is almost ready. We put the legs into the inside of the grill. It remains to attach a handle to it for easy carrying. We make it from three short bars. We weld them together from one end. To the second we weld the cross-member from the cropping of the square.

Heating the rods from the base, twist them and give the shape of a pigtail. We heat the finished part at the bend in two places, and cut off the excess with the grinder.

Now the handle can be welded to the end of the barbecue, and feel free to go on a trip to nature!

Watch the video on how to make a barbecue

Share

Pin

Tweet

Send

Share

Send