Share

Pin

Tweet

Send

Share

Send

Despite the large and varied number of names and models, hair clippers, for the most part, have the same main parts and details. They (machines) may differ in shape, color, weight, but the working part of all is assembled and functions according to the same principle. And that means they are disassembled the same way. Well, or almost the same - the only thing is that for more modern models, disassembling the working part does not require any tool, while for older models, the outer knife is removed using a special key. Professional cars are another matter; they most often have self-sharpening knives made of more expensive and high-quality steel and the assembly of their working part may slightly differ from the usual one. It costs several times more than a conventional machine. In addition, you can’t buy it in any simple store where they sell the corresponding goods ... But today we will focus on the usual, amateur (so to speak) hair clipper.

After some time of use, it happens that the machine begins to tear and pluck the hair when cutting. The feeling is not the most pleasant. Some owners and users of this device mistakenly believe that this is a blunt machine knives. In most cases this is not so! First you need to disassemble and thoroughly clean the working part of the device.

Will need

- Water.

- Detergent for dishes.

- Vinegar 9%.

- Cotton fabric.

- Oil.

- Toothbrush.

- Disassembly key (depending on model).

- Alcohol (you can vodka).

Machine cleaning

We disassemble the working surface.

Despite the delicate work and purpose of the device, its details are simple and not numerous, so even a person who is very far from any kind of mechanisms will not get confused in disassembling and assembling.

And so, sorted. Now every detail is thoroughly cleaned of hairs and dust with a toothbrush.

Included with the machine, most often, there is a small brush and a small tube with oil, but there’s not much to clean with such a brush, so to speak! Further, if there is rust on the metal parts (this happens after cutting wet hair, and also thanks to the manufacturer who used low-quality steel!) We lower these parts into a container with 9% vinegar for five to eight minutes, after which we remove the rust with a brush. Thoroughly rinse all parts in a container with water and detergent, rinse them with clean water, and leave to dry on a clean cloth.

After all the parts dry out of moisture, we also wipe them thoroughly with a clean, dry cotton fabric. Putting the car back. When assembling, drip oil on springs and all moving parts.

After the final assembly, we drip a drop of oil directly onto the cutting teeth of the knives of the machine, turn it on, and let it work for a minute and a half. During this time, excess oil will protrude from the joints and openings of the mechanism. Turn off the machine, wipe the excess oil that protrudes, and wipe the outer blade (which comes in contact with the skin) with alcohol. In most cases, this is enough for the machine to work as before when you first used it. However, if the problem persists, then it really means the knives of the machine. Will have to sharpen.

Will need

- Emery paper (nulevka), or the corresponding granularity a wide whetstone.

- Absolutely flat surface.

- Leather or coarse cotton fabric.

- Goy or pasta paste.

- Pure water.

- Oil.

- Sprayer for water.

- Alcohol.

Knife sharpening

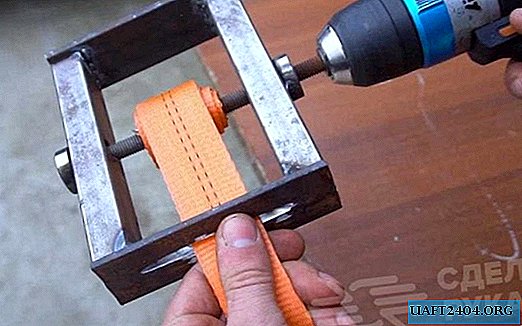

I will not sharpen the blades of my typewriter, as I recently did it, but to show it clearly, I will demonstrate on them. So; repeat the disassembly procedure. We lay sandpaper on a flat surface (you can use a wide grinding whetstone or an abrasive disk of the corresponding grain size, the main thing is that they are smooth!), Spray the abrasive with water from the spray gun and proceed to sharpening.

We sharpen with the teeth forward (away from us). That is, the blade is returned back to itself without touching the abrasive.

Too much pressure on the blade is not necessary. We hold it on the grinding surface only slightly holding and pushing it - for such a thin sharpening, the pressure force of its own weight and your pressure will be quite enough for it while holding the plane of the blade on the abrasive plane. Repeat these movements 30-50 times. Do not forget to wet the surface as water evaporates during sharpening. After such a “rough” sharpening, it is necessary to correct the teeth with smaller abrasives: chalk or goy paste. On a flat surface, spread the skin, smear goy paste on it (for lack of such, you can use coarse cotton fabric and ordinary chalk) and in the same way as with the previous sharpening, repeat the procedure - with teeth forward, 30-50 times.

Then we wash the blade, dry it, wipe it with a dry cloth and, not forgetting to grease the surfaces washed on the blade, put the machine back. Also, it is unforgettable to drip oil on the teeth, and let it work idle. Only this time, about three minutes, so that the freshly sharpened teeth are rubbed against each other. After that, wipe the blade with alcohol. Now the machine will cut as it should, without unpleasant "surprises"!

If, after all of the above procedures, the machine continues to pinch and pull the hair (which is unlikely!), Then the steel from which the blades are made is very poor quality and useless. All that remains is the replacement of these blades. Unless, of course, you can find them on sale, which is very difficult. Perhaps only in some online stores.

Share

Pin

Tweet

Send

Share

Send