Share

Pin

Tweet

Send

Share

Send

As you know, polyurethane foam quickly hardens in the open air, which is good when applied to building structures. But if this happens inside the construction gun, then there will be no possibility to continue work on filling gaps or sealing joints.

Is it really because of this that you have to buy another instrument, the price of which starts at 500 rubles? But what if the second happens the same? So on the pistols for a short while and go broke.

But not everything is so gloomy. Firstly, there is a universal foam cleaner in cans, which costs about 300 rubles. Its contents may be enough for two or three cleanings, that is, each such procedure will cost you 100 rubles.

Is it possible to do without this expensive tool if it became necessary to clean the construction gun from the mounting foam that dried inside it? Yes, such an opportunity exists. You can make a very simple device yourself, which will cost you a total of 5 rubles and can be used as many times as needed.

Work on the gun flushing attachment

For its manufacture, you will need an old cylinder from under the mounting foam, or rather, its upper part, which can be easily and accurately cut using a carpentry knife.

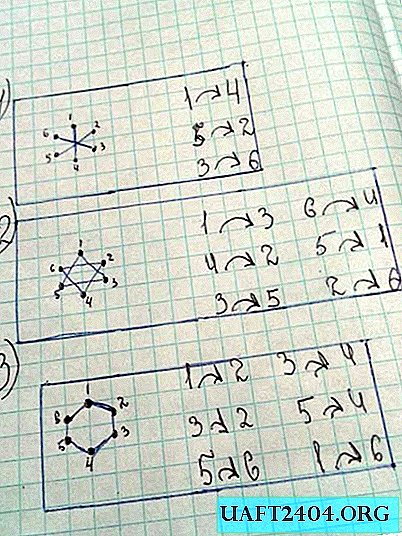

We clean it from the old foam and remove the valve using the following simple manipulations.

We insert the rod into the hole and knock it with a hammer until it rests against the valve.

Then, on the reverse side, yielding the valve, tear off using pliers. Moreover, the lateral short tube, which opened after removal of the valve, should remain in place.

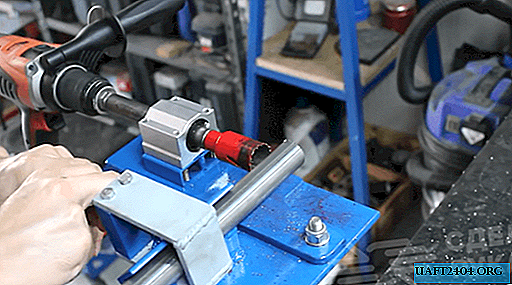

Next, we paste a 20 milliliter medical syringe, since it is precisely it that fits tightly into the valve opening. The syringe in volume less than indicated will hang out, and more will not enter.

After these manipulations, use a glue gun to fill the junction of the syringe and valve with epoxy resin or some other suitable means. It is necessary to allow some time for the glue to harden, after which the device is completely ready for washing the construction gun from the mounting foam that has dried in it.

In principle, one can limit oneself only to gluing the tip of the syringe in the hole where it is inserted. But it will be more reliable to fill the connection completely with glue, since the device will have to be twisted and unscrewed, making certain efforts. In addition, during washing, rather high pressures arise in it.

The process of cleaning the gun from dried foam

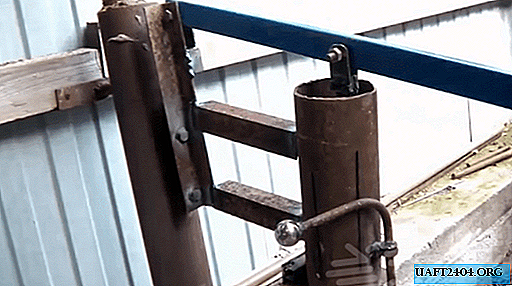

Further, it is necessary to unscrew the gun as soon as possible with the remaining inside and hardened mounting foam from the can, since the valve often does not work. About one solvent syringe is poured into the can to clean the valve.

Then we install our device on a construction gun and wrap it until we hear a hiss, which indicates that the device is fully twisted.

Pour solvent “646” into the syringe using another syringe, insert the piston and start flushing the gun. To do this, squeezing the piston, press the trigger of the gun. A portioned solvent will gradually contribute to the removal of hardened foam from the gun channels, previously diluting it. For complete cleaning of the tool, two refills of the syringe are sufficient.

Usually, after using our device, so that it is ready for use the next time, it must be rinsed and at the end fill up a full syringe of water and leave until the next use.

Summary remarks

Still, the syringe in the cap must be filled with the same epoxy. Here retention and tightness will be ensured due to the large volume of glue. Otherwise, nothing will work: to stick plastic to plastic is practically impossible.

The experience of many craftsmen shows that if the can with foam is screwed correctly, it does not harden during storage for months. Only at the end of the tube can a film form which cannot be removed during storage. It is she who does not allow air to penetrate the tool and protects the foam in the gun from hardening.

Share

Pin

Tweet

Send

Share

Send