Share

Pin

Tweet

Send

Share

Send

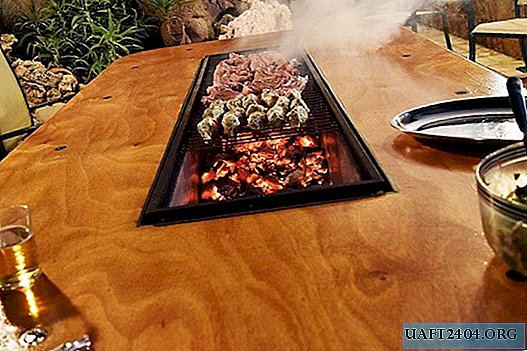

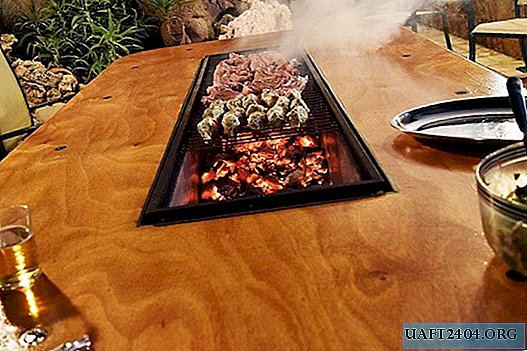

The table that we want to talk about today is a comfortable combination of a barbecue and a dining table for a large company. A roasting pan is mounted in the middle of it, on which everyone can cook for himself what he likes. Such an innovation will not leave indifferent even the most fastidious gourmets and vegetarians in food.

Product Specification

Designed table for 12 people. Its dimensions: 250cm x 120cm.

To make a table you will need:

- Profile pipe 60x60 mm - 14.5 m.

- Profile pipe 60x30 mm - 3.2 m.

- Sheet metal, thickness 1-2 mm.

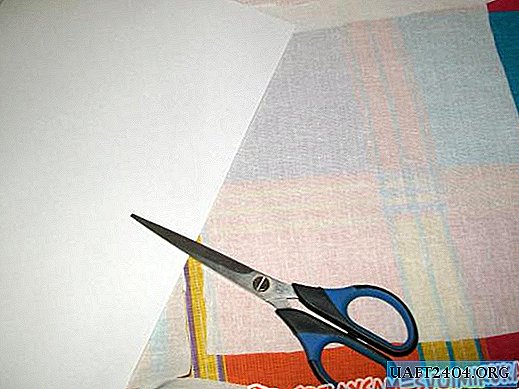

- Plywood 18-20 mm.

- Self-tapping screws, wood glue, heat-resistant sealant.

- Plastic plugs for professional pipe 60x60 mm - 4 pcs.

- Sheet of thermal insulation wool.

- Flat slate.

- Primer, varnish, solvent.

The tools are as follows:

- Bulgarian (angle grinder).

- Electric router (slotted cutters, semicircular moldings).

- Circular or jigsaw.

- Grinder machine.

- Electric welding, plasma cutter.

- Drill or screwdriver.

- Spray gun, compressor for finishing.

- Hand tools are standard for every home workshop.

Table frame manufacturing

The table frame consists of a frame and four legs made of a professional pipe 60x60. We start manufacturing it with a frame whose dimensions are 220x100 cm.

We cut the workpiece with a grinder (angle grinder) or an end saw. The ends of the workpieces for fillet welds are cut at a mustache at 45 degrees.

For more precise welding, frame parts should be aligned evenly in the same plane on the floor or work table. After grasping, scald the joints. We reinforce the internal space of the frame with additional guides that form the area for the barbecue tray.

At the corners we set the legs of the table. Their length is 73 cm. Having verified the right angle in several planes, we weld the joint. It will be more convenient to clean all joints with a grinding wheel if you put the table on its legs.

Now you can place a plywood sheet on top and turn it into a countertop. To do this, cut it to the size of the table, round off the sheet ends with an electric milling cutter, and activate the outer edge around the perimeter of the workpiece with a semicircular cutter. It was the turn to try on plastic plugs on the ends of the legs.

BBQ preparation

Having decided on the size of the tray, we select the middle of the countertop under it by an electric mill. We make the capacity for coal from sheet steel in the form of a box with an open top. Individual elements can be cut by welding or with a angle grinder.

Having scalded the joints of the box, we bend its edges so that it does not fall into the niche of the table, but at the same time it is removable. It remains to clean the welded joints, making them more aesthetic.

Covering table parts

From the remaining plywood, we make the lining of the visible areas of the table - a barbecue box and legs. Sheathing elements can be cut on a circular or jigsaw. You can pull off the lining on carpentry glue or moisture-proof PVA, further strengthening the joints on nails or self-tapping screws.

Preparing to assemble all parts

We prepare the countertop for fixing, making preliminary holes in it from the front side. We expand them with a pen drill for wide caps of fixing bolts. You can also cover with gaskets made of flat slate table frame in the adjoining area of the tabletop. Round the legs of plywood with a milling cutter and finish with vibration grinding. Now they can be easily put on the legs, smearing the metal with liquid nails, and closing with plastic plugs.

Barbecue box insulation

Since we are talking about an open hearth with coals, tanks under it need protection against fire. Sheet metal can become very hot, and so that the plywood or knees of the guests are not burnt, we will lay them with fireproof cotton wool throughout the inside of the box. Only a few centimeters of this heat-resistant material is enough to isolate heat from the fryer. We close it with sheets of flat slate, fixed on self-tapping screws. Joints pass high-temperature sealant for fireplaces and chimneys.

On furniture bolts with wide hats we fix the countertop to the frame. To prepare the surface of plywood for finishing will help a vibration grinder. Recesses from the mounting bolts on the table surface can be filled with epoxy resin or a suitable sealant.

For the final decoration of the table we use varnishing. The best tool for applying varnish is a spray gun with a compressor unit. If the surface of the plywood is primed, one coat of varnish is enough for you to get the perfect coating.

A lid has also been made, with which you can close the hole by stinging the fryer when you do not need to fry anything, but just sit with friends at a large table.

Put the meat on the grill.

The table is ready, you just have to fill the barbecue box with burning coals, put grills, food on it and enjoy live chat in a friendly company.

Share

Pin

Tweet

Send

Share

Send