Share

Pin

Tweet

Send

Share

Send

Materials:

- board or furniture board 20 mm 40x20 cm;

- rail 50x30 mm;

- self-tapping screws;

- plywood 10 mm;

- door hinges - 2 pcs.;

- bolt M12;

- bearing;

- washer M12;

- M12 nuts - 2 pcs.;

- M8 bolts with nuts - 2 pcs.

Circular table assembly

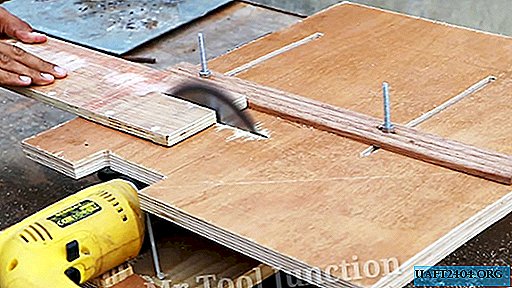

On the basis of a circular machine, legs are set from a board or board 40x20 cm. In their quality trimming rails are used. They are screwed in the corners with a pair of screws.

To emphasize the fastening of the drill, it is necessary to screw a strip of plywood to the edge of the base with an extension from the trim board. You can simply make a similar design from a sawdust rail.

In the center of the shield, a transverse cut is made under the saw blade. To do this, first drill holes at its edges, and then they are connected by a double cut.

To fix the table top of the machine, a piece of plywood is screwed onto the side of the base. Its height is selected individually for the diameter of the saw wheel. A pair of door hinges is attached to it.

A hole is drilled between the cutout for the saw blade and the extension for the diameter of the drill handle. A sawn handle is inserted into it and screwed on with screws.

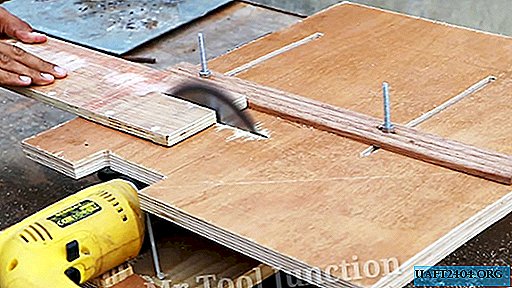

For further assembly you need to put the saw blade. To do this, a bearing is put on the M12 bolt, a circle, a washer and 2 nuts are put. The drill is installed in a fixed handle. A circle is clamped in her cartridge.

On the frame of the table requires the installation of a transverse bar of plywood. A hole is drilled in it for the diameter of the bearing so that it enters with force. It will serve as an additional mount for the disk and support the countertops.

Next, a plywood worktop is installed. It is attached to the door hinges. After the drill starts, and the countertop lowers onto the saw blade. He will cut a window for himself.

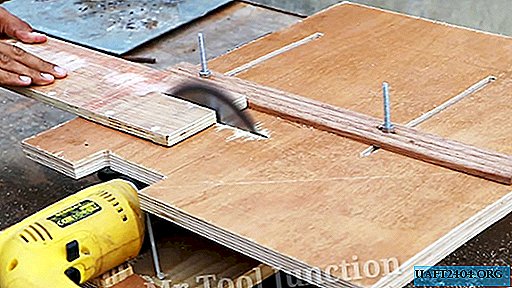

If the tabletop partially covers the drill, then in such a place it is better to cut it off so that the tool normally cools. Also on it you need to make cuts to secure the parallel stop from the rail.

The resulting circular table, in spite of the low speed of the disk, can very well help with the sawing of the laminate. It is convenient for them to cut into small pieces, for example, for assembling stools or boxes.

Share

Pin

Tweet

Send

Share

Send