On the clamping stop of a standard F-shaped or other joiner's clamp there is a plastic “cap” that can crack if you squeeze the clamp strongly.

Without plastic coating, the pressure stop leaves dents on the wooden blanks. However, simple repair of the F-clamp will help solve the problem.

This will require a metal washer with a diameter slightly smaller than that of the pressure stop (in this case 20 mm) and a plastic bottle cap. You will also need a gas burner or a building hair dryer.

The main stages of work

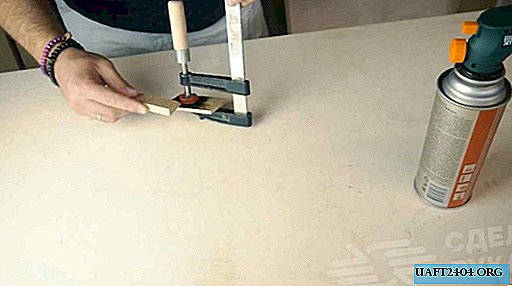

A washer must be placed on top of the pressure stop, and then a plastic cover. After that we rest the lid on a small piece of plywood and twist the clamp handle all the way. The clamping “penny” itself needs to be aligned in the center of the lid.

At the next stage, using a gas burner, the author melts the lid. If possible, it is better to do this with a building hair dryer - it will turn out more accurately.

When the plastic "softens", use a piece of plywood or another improvised item to smooth it in such a way as to completely cover the upper part of the stop.

Then leave for a while, so that the plastic hardens. The most important thing is that the movable pressure stop remains as mobile.

Otherwise, when tightening the workpieces, the clamp will constantly slide. For details on how to do the repair of the F-shaped clamp with your own hands, see the video on the website.