Sometimes the grinder does not manage to crawl to the corner joint of the parts, for example, to clean the weld. Either the sweep circle itself is small, or simply uncomfortable.

Just for such problematic cases, the author suggests making a do-it-yourself extension nozzle for a grinder (angle grinder) with his own hands.

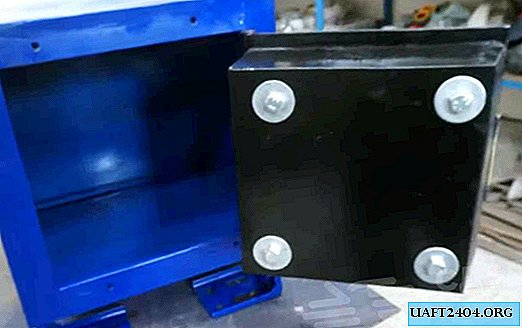

The device itself is very simple to make. For this, the author uses pieces of a profile pipe, a piece of a round pipe (for a collar), and also two pulleys: one is mounted on the Bulgarian shaft, the second is attached to the end of the extension cord. A belt is pulled over the pulleys.

Thanks to such a homemade nozzle, the grinding wheel reaches the corner joints without any problems. In principle, the idea itself and its implementation is understandable. But another question arises: is it practical to use such an extension nozzle, and is it worth the time to make this thing?

Advantages and disadvantages

In fact, the advantages of using this nozzle are obvious: now you can easily reach the hard-to-reach places with a cleanup circle.

However, it is worth noting that the design itself has a number of flaws. In particular, there is no protection on the belt and on the disk, and therefore the risk of injury increases, and this fact reduces the practicality of this device to nothing!

What do you think about this homemade product? More information about the extension nozzle for the grinder (angle grinder) can be found in the video on our website.