Having a gas burner and sharpener in the household, you can become the owner of a set of wood cutters. This will require skill, desire and several table forks.

And the first thing you need to select the appropriate samples for the manufacture of cutters. We heat the prongs of the forks and lower them into salt water.

Then we try to break off the tip. If it crunched like glass and broke, it will do. If it bends and does not break, then it will not work to harden the cutter. So, such a plug does not fit. For incisors, only those forks whose teeth break off should be taken.

Tool manufacturing process

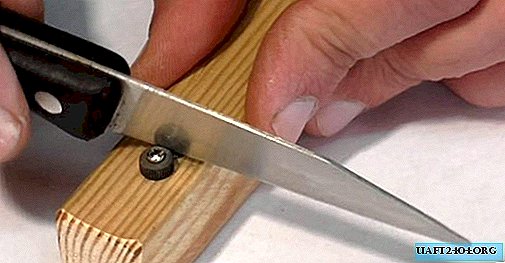

On the anvil, the master aligns both forks. Marks line sketches with a marker. Using a sharpener, he achieves the desired shape. Then he warms the fork with a thick handle with a gas burner, flattenes the cutting surface.

From the other end of the resulting workpiece, the master makes a shank. He puts sandpaper on the stone and grinds it, and then polishes it. On the grinder grinds the cutter at a certain angle.

After that, you can proceed to hardening. Heat to red and immerse the part in oil. Next, the master makes a "lazy" vacation on low heat.

It is important here to monitor the shade. As soon as the yellowness goes along the blade, we cool it. We put on shanks, handles. The result is a ready-made set of three different incisors, which will be useful for the novice master.