When it is necessary to weld a complex structure of several parts, it is often necessary to call someone for help, since it is not convenient to hold the workpieces simultaneously with one hand. Alternatively, you can use a large number of different clamps, clamps and stands, but this will take a lot of time.

So let's make a simple metal helper called the "third hand." Its difference from other similar devices is the presence of a clamp.

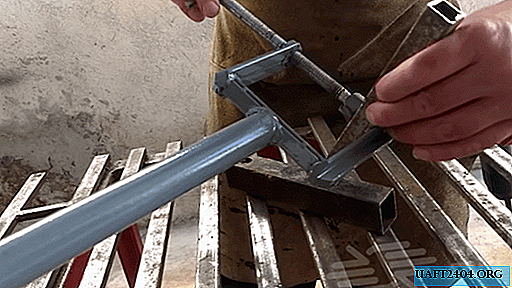

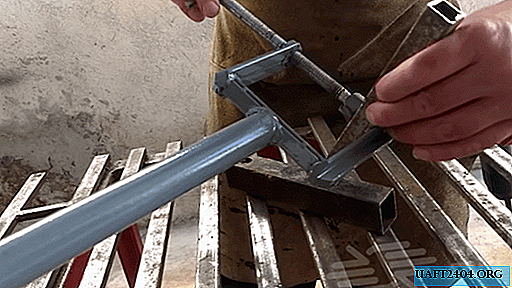

To begin with, take two pieces of a square profile pipe (about 5 cm each), make holes in them. Two pieces of a round pipe should pass relatively freely in them. We weld the end of a round pipe to one segment from the side of the whole part.

The process of making a comfortable "third hand"

We wind the nut onto the stud and weld it to the outside of the square profile. Then we pass the second round pipe to the workpiece.

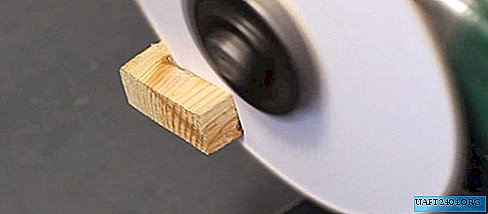

We sharpen the hairpin on both sides, wind the nuts around the edges, weld them and cut them with a grinder. It turned out two pointed screws.

Next, we will manufacture the second locking mechanism. We put a nut on one of the screws and weld it onto the second square section of the profile. We pass the first pipe through it.

Now you need to attach the future "third hand" to the table on which the work will be performed. We will use welding for this. We make a holding part from a long screw and corners welded together. The approximate size is 10x10 cm. We also weld it to the pipe.

We add handles to the fixing pointed screws. It remains only to clean the welds and paint the structure. Homemade is completely ready for work.

Using the "third hand", you can easily hold the parts, rotate them at the desired angle, move left and right, raise and lower. This greatly speeds up and simplifies the process of cutting, welding and processing products.