In any workshop or garage, a clamp is indispensable. Moreover, it is not necessary to spend money on its purchase. A reliable clamp can be whipped up from improvised materials. For example, old car brake pads are suitable for this. Why not?

First of all, we connect two brake pads in such a way that the letter "C" is obtained, and then we scald. We clean the resulting welds with a grinder with a petal circle - this will look more neat.

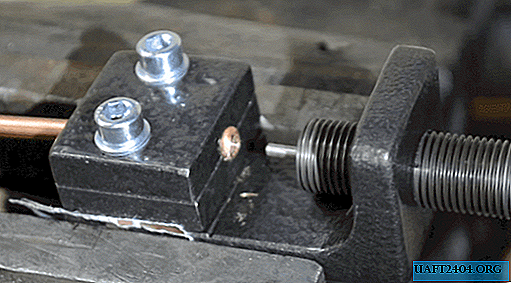

Then, two elongated M12 nuts and a piece of a stud of suitable length with a diameter of 12 mm will be required. We screw the nuts on the stud, and then weld along the edges of the frame of the future clamp.

The main stages of work

Next, you need a nut with a press washer. Clamp it in a vice and drill a hole of the desired diameter. Then we insert the M6 screw, on top we put the usual washer and this whole thing needs to be scalded. As a result, you should get such a “nice” detail.

After that, we drill a hole from one of the ends of the studs and cut the thread for the M6 screw. Next, we cut off a small piece of the stud with a grinder and weld a nut to the end.

Then it remains only to slightly modify the main hairpin, after which you can proceed to assemble the homemade product. For details on how to make a clamp with your own hands from old brake pads, see the video on the site.