A belt grinder (also often called a grinder) is useful in any home workshop. Moreover, it can be used to grind not only wooden workpieces, but also metal.

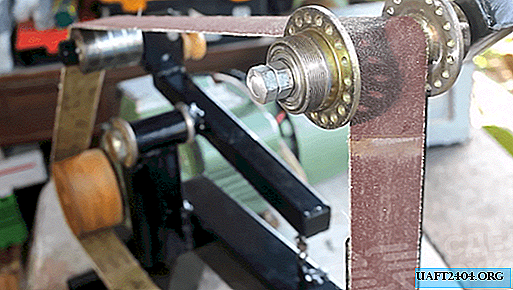

If you have a working electric motor, a few metal scraps and a pair of bicycle sleeves, then a belt sander can be made independently. Moreover, the design will be very simple, but at the same time reliable.

First, cut four pieces of the corner and weld a square frame. We weld it to the profile pipe 40x40 mm. Then we cut out a small groove with a grinder, into which we insert a piece of a smaller profile - 20x20 mm, and scald.

The main stages of work

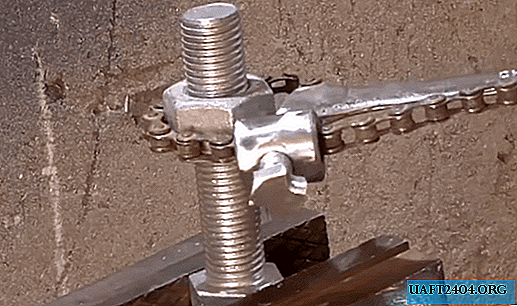

In a profile pipe 40x40 mm, we make two triangular cuts, and bend it in these places at a small angle. We weld the formed seams. Next, cut a piece of profile 20x20 mm, make two cuts at the edges, then bend and also scald.

We reinforce the profile of 20x20 mm with a steel strip, which we weld on the side. After that, it will be necessary to drill one through hole at the edges. We insert bushes from the bicycle, and fix them with nuts.

We connect two structural elements together by welding. From a piece of wood you need to cut a drum that will be worn on the motor shaft. We install the electric drive on a frame from corners.

Then proceed to the assembly of the grinder. The detailed process is clearly demonstrated in the video.