Bearings, as you know, are made of very high quality steel, so they are ideal for forging homemade blades and knives. It is noticed that among the masters who specialize in the manufacture of knives, Swedish bearings are especially appreciated, however, domestic-made bearings are quite suitable for this homemade product.

It should be noted that good hunting knives are made from the bearing cage, as well as large kitchen cleats that easily cut meat with bones, while they keep sharpening for a long time - even with heavy use they can be sharpened every 6-8 months, sometimes even less often.

The main stages of work

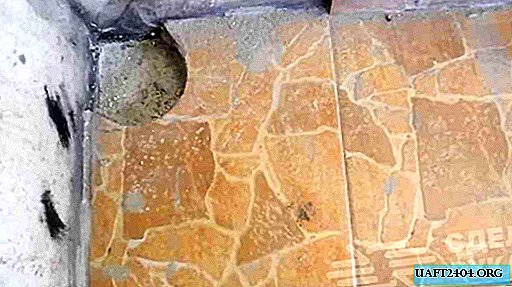

First of all, it is necessary to cut the outer and inner bearings of the bearing in order to remove the "insides" - we clamp the bearing in a vice and make it drunk with a grinder. Then the outer clip must be straightened. To do this, we heat it first in the furnace red-hot, and only then just unbend the ends.

Subsequent alignment of the workpiece is more advisable to carry out using a pneumatic hammer, however, you can do with a manual sledgehammer, beating the clip on the anvil - but in this case you will have to spend more time.

After a straight plate with a handle is obtained from the round bearing cage, we cut the workpiece to the size of a grinder and proceed to machining: we clean and grind the surface, round off the edges, and also make a cutting edge.

Then we drill three holes in the tail end of the cleaver and make a handle from plywood or wood - steel rivets can be used as fasteners. For a detailed process for making a cleaver knife from a bearing, see this video.