In the process of construction and repair work, it is often required to cut steel, copper / aluminum or plastic pipes into pieces of different lengths. And not just cut off "from the flashlight", but do it as smoothly and accurately as possible so as not to waste time on additional machining.

At home, for cutting pipes, they usually use either a grinder with a cutting wheel, or a hacksaw for metal. However, when you want to make an even cut, it is more advisable to use a pipe cutter. This device will speed up the process and make it much less time-consuming, and you can do it yourself from the trash.

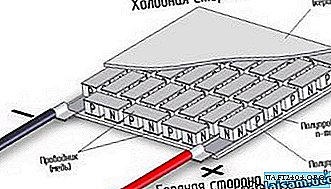

The design itself is very simple:

- round cutting roller;

- chain for fixing the pipe;

- main frame from the profile;

- hairpin handle.

The principle of operation of a homemade pipe cutter is based on the use of mechanical rotation force: the pipe is installed in a vice and fixed by a chain. Using the feed knob, we press the cutter and begin to rotate the pipe cutter - a thin groove is formed in the wall of the steel or plastic pipe, which deepens as it rotates.

How to make a pipe cutter with your own hands

We cut the profile pipe to size. In two rectangular plates we drill holes on one side and fasten the roller cutter with bolts. Then insert the part into the pipe and scald. Next, you need to weld two short pieces of round timber to the edge of the profile (pieces of the old bolt can be used instead).

At the last stage of work, we weld a piece of a motorcycle chain to the profile pipe, to the end of which we fasten a long pin (feed handle) by welding. Then, two guide nuts must be welded to the profile - we thread a stud into them, at the end of which we wind the lamb. Homemade pipe cutter is ready!