Stranded bowden cables, which are used to transfer mechanical force in cars and motorcycles, are in most cases made of carbon steel, and therefore are an excellent raw material for forging knives. They hold sharpening well after hardening.

Another advantage of using cables is to obtain a heterogeneous pattern on the surface of the blade, characteristic of Damascus steel. It should be noted that the manufacture of a knife from Bowden cables from a motorcycle is not an easy task.

To do this, you will have to make a little more effort than forging a blade from an ordinary steel bar. However, the end result is worth it. Therefore, if you have experience in blacksmithing, make yourself such an unusual blade from homemade damask steel.

Making a knife from cables

We lay the cables vertically in a square metal “glass”, fill it with cement to the very top, and then weld the lid from a steel plate of suitable sizes. A piece of reinforcement will need to be welded to the lid in order to more conveniently forge the workpiece.

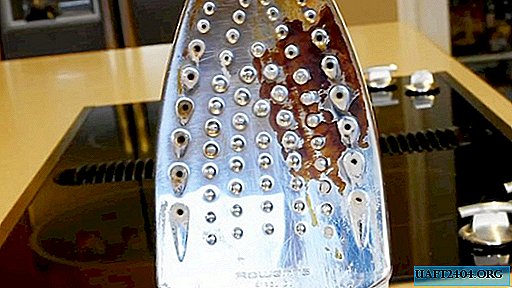

Next, we heat the workpiece red-hot and give it the desired shape under a hydraulic press. This process is not quick, but in this matter it is important to be patient. First, we form a bar of the required size, then on the hydraulic hammer we "beat off" the plate.

At the next stage, we make the contours of the knife, after which we can proceed to grinding and hardening the blade. See the video for the detailed process of creating a knife from cables. Write what you think about this method of making blades at home.