As experienced joiners and home craftsmen often like to repeat: "There are never many clamps in the household." And it's hard to argue with that. Different types of clamps are used for specific work, so it’s good when the workshop has a large supply of factory clamps and home-made appliances.

In this article, we will consider how to make a reliable, practical and easy-to-use F-shaped clamp in your own hands. This clamp is adjustable, so it is ideal when you need to fix workpieces of different sizes and shapes on the work surface or between each other.

The manufacturing process of the F-shaped clamp

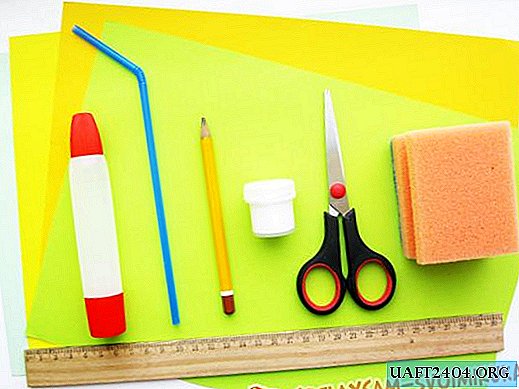

From a steel strip 4 cm wide, cut two pieces 15 cm and 7 cm long. The edge of the first piece is cut off by a grinder at an angle of about 45 degrees, and then we weld the workpieces perpendicular to each other. The free end of a long section of steel strip is welded to the top of the pipe. A piece of square must be welded to the stud.

We put a metal sleeve on the pipe, to which you need to weld a piece of strip with an elongated nut at the end (under the stud). After that, in the sleeve itself and the pipe we drill holes for the bolt fastening. At the last stage of the work, we cut another piece of steel strip, on one side of which we make a slot for the diameter of the pipe.

Of the main advantages of a homemade long clamp, light weight, the ability to fix large parts, as well as high strength. For a detailed process of making a homemade F-shaped clamp, see the video on the site.