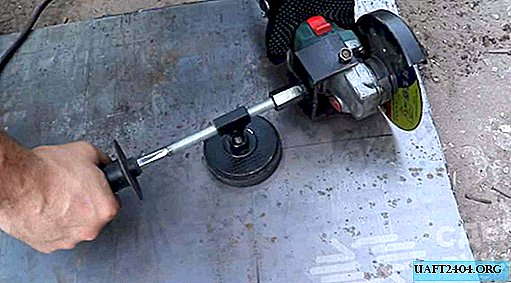

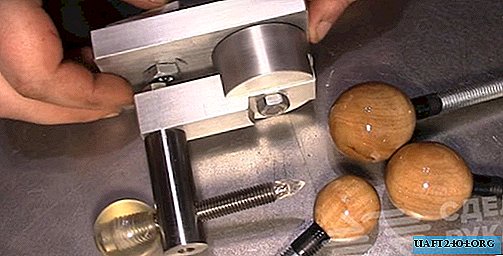

Having made such a device, you can quickly and easily grind balls of different diameters from wood or plastic on any lathe (even at home). You can use such balls as tips for various levers or for homemade products. Well, let's get to work?

Necessary materials:

- duralumin blank with a diameter of 40-50 mm;

- plate 100x50 mm (thickness 20 mm);

- steel bearings of different diameters.

Step-by-step device manufacturing process

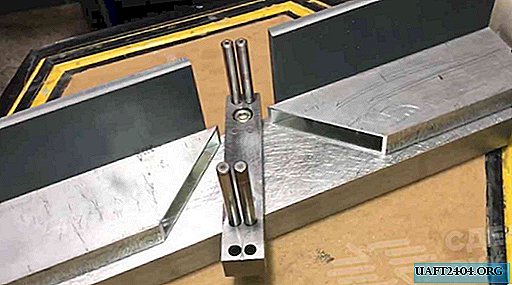

First of all, it is necessary to machine a duralumin blank on a lathe: drill a hole in the center with a 6.7 mm drill, and then make a groove for the bearing. In the metal plate, you also need to drill a hole for the bolt and bearing of a smaller diameter.

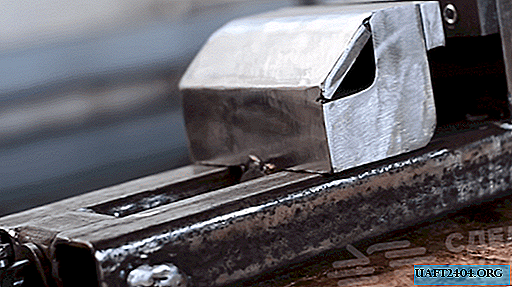

When the bolt is twisted, then on one side it will attract a small bearing, and on the other it will rest against the washer. Then you need to make a hole in the plate for fixing and you can do the milling of the part. After machining, it is necessary to prepare a metal bar and make it a "seat" in the blank - for this you will need to make a bore to the thickness of the prepared bar and make a longitudinal channel for the entire width of the round blank using a cutter.

In the metal bar you need to make several holes. All elements of the future design for greater attractiveness can be further sanded. At the final stage of work, you will need to make a rifled "trunk" and drill a through hole in it. A hole must also be made in the body of the hairpin in order to fit a cutter there, which will carry out all the basic technological operations.

How does it work in practice?

You can see the detailed assembly process, as well as see how to use this device, in the video on our website. One thing is for sure - this device will definitely like it and will be useful to everyone involved in turning works.

# 1 How to make a cutter for making balls

submitted by  Anton 07.05.2018, 12:38

Anton 07.05.2018, 12:38

- Report

Add entry

Picture Video Audio Text Insert code