The author decided once again to "invent a bicycle", and to slightly modify and modernize the factory manual clamp, "diluting" it with the details of an old bicycle sprocket.

Good or bad - you judge. Well, we will briefly describe how to make such a device with our own hands.

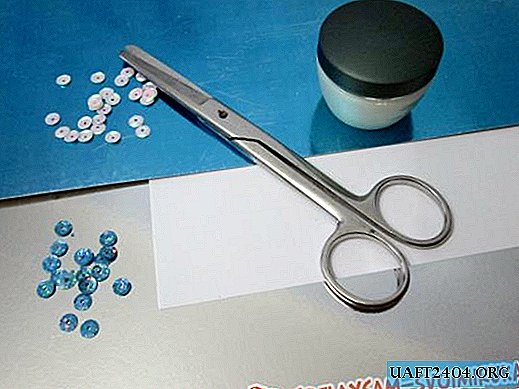

First of all, the master cuts out the middle of the bicycle sprocket, and then cuts the outer "contour" into two identical parts. These will be the new jaws of the manual clamp.

The main stages of work

Two parts that will be needed for making homemade products will need to be cut from the previously cut out star core.

Next, in one of the halves of the bicycle sprocket, you need to drill one hole, after which, with the help of a bolt and nut, fix two workpieces from the "core".

From a small piece of metal strip, the master cuts off the pressure plate and welds it to the moving parts. The same plate is welded to the second half of the sprocket.

At the last stage of work, it remains only to weld large home-made jaws to a manual clamp. As a result, according to the author, a more practical and convenient tool was obtained.

However, it is perhaps easier to use clamps without altering the manual clamp itself. For details on how to modify the manual clip using a bicycle sprocket, see the video on the website.