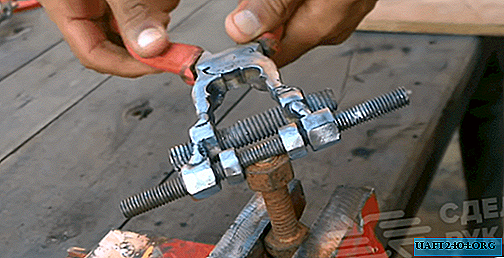

Homemade folding holder is compact in size and good ergonomics, and therefore useful in any home workshop. It fits without problems not only in the drawer of the table, but even in your pocket. With this tool you can cut round logs, wire and even thin reinforcement. In general, the application on the farm will always be found.

Folding holder manufacturing process

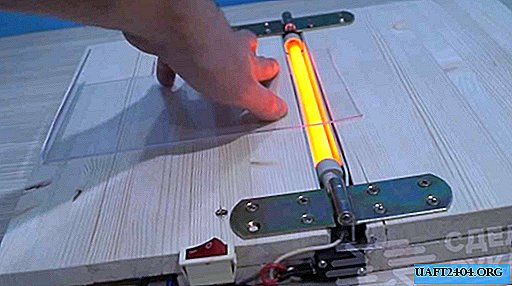

For this homemade product you will need two thick aluminum plates, in which you must first drill a through hole, and then cut a longitudinal groove for the entire length of the workpiece on a band saw or using a conventional jigsaw. In the place of the cut, the inner edges must be treated with a mill, and the outer surface of the aluminum plates should be well sanded.

It is advisable to round the corners of the parts. At the ends of the workpieces, it is necessary to drill a through hole, and then connect them using a wooden block and metal dowels made of thick wire or a steel rod. After that, we process the surface of the part with the help of an electric file, giving it a rounded shape.

Assembly of the main parts of the device

A small rectangular piece is cut from a thick piece of metal, which is given the desired shape using a milling machine and a hand file. This part is attached to the handles instead of a wooden block. It makes a slot for installing a saw blade for a hacksaw for metal.

Then all the structural parts are connected to each other using a steel rivet and the sheet is fastened to the metal (it will first need to be cut to the desired size). The manufacturing process of the folding holder, see the video on the site.