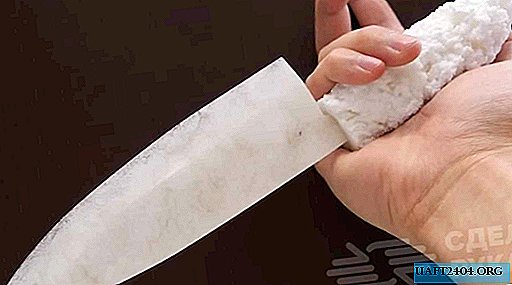

This review presents a very unusual and creative idea for making a knife at home. The knife is made of foam. Do you think this is impossible? The author proves to us the exact opposite.

To make a kitchen knife, you will need polystyrene (expanded polystyrene), orange peel, 96% alcohol, a jigsaw, a spray gun, grindstones for sharpening a knife blade, a hair dryer and a little imagination.

First of all, you need to remove the zest from an orange and grind it in a blender with a small amount of water. We heat it over a flame in an airtight container and use a tube (coil) and a cooling container to isolate concentrated essential oil.

The main stages of work

Oil made from orange peel can melt the foam. Pour alcohol into the weld mass and then mix the resulting mixture until a homogeneous lump forms.

Transfer this lump into the pan and heat it, gently stirring and not boiling. As a result, we get a denser mass. Smooth it with a silicone mold (to prevent sticking). Cool the workpiece.

Now let's handle it. The foam mass is heated with a construction hairdryer and gradually we get the approximate shape of the future handle. Press one edge to the heated pan and get something like a guard. With a heated tool, make a hole for the shank.

The final touch and you're done

Now proceed to cutting the blade itself. We outline the necessary shape and cut it along the contour with a jigsaw and spray gun (cooling the surface of the cut, otherwise the polystyrene melts from heating). We finally grind the future blade to the contour lines.

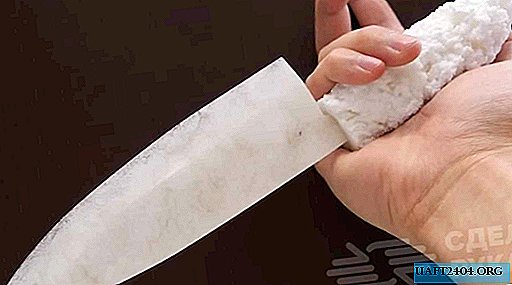

Next, we begin to sharpen the knife. Grind with wet stones (preventing the blade surface from heating up).

We connect the blade and the handle, and our knife is ready. For details of manufacturing, stages of work, and possible errors during operations, see this video.